Introduction:

In the fast-paced world of manufacturing, efficiency, precision, and compliance are the cornerstones of success. This is where Manufacturing Execution Systems (MES) come into play. In this blog, we will delve into the vital role that MES plays in optimizing manufacturing processes, and we’ll also explore the significance of SAP Manufacturing Execution (SAP ME) in achieving these goals.

According to a report by Transparency Market Research, the global MES market is poised to reach a substantial revenue of approximately US$18.06 billion by the conclusion of 2025.

What is a Manufacturing Execution System (MES)?

A Manufacturing Execution System (MES) is a sophisticated software system that acts as the nerve center of manufacturing operations. It monitors, tracks, documents, and controls every aspect of the production journey, from raw materials to finished products.

MES software bridges the gap between Enterprise Resource Planning (ERP) and process control systems, providing real-time data to decision-makers to enhance plant floor efficiency and production optimization.

The Benefits of MES:

- Improved Quality Control:

MES enables real-time transmission of quality control information, allowing companies to halt production immediately when issues arise. This minimizes waste, reduces scrap, overages, and rework, ultimately enhancing product quality.

- Increased Uptime:

MES generates realistic production schedules by balancing resources like personnel, materials, and equipment. It integrates scheduling and maintenance to maximize asset utilization, increasing uptime and overall equipment effectiveness (OEE).

- Reduced Inventory:

By updating inventory records in real-time, MES helps in inventory management, reducing just-in-case and work-in-progress (WIP) inventory. This leads to cost savings in manufacturing, transportation, storage, and inventory monitoring.

- Paperless Shop Floor:

Eliminating paperwork minimizes human error and ensures that shop floor data is immediately available to decision-makers, facilitating real-time decision-making.

- Improved Product Tracking and Genealogy:

MES traces the entire production cycle, aiding regulatory compliance for industries that must adhere to strict regulations. It provides a comprehensive history of each product, ensuring transparency and traceability.

Core Functions of MES

In 1997, MESA (Manufacturing Enterprise Solutions Association International) defined 11 core functions that remain pivotal in today’s Manufacturing Execution Systems (MES):

- Resource Allocation:

Real-time tracking of machines, materials, and labor for efficient resource allocation.

- Scheduling:

Optimizing activities based on priorities and resource capacity.

- Dispatching:

Managing real-time data flow for agile production adjustments.

- Document Control:

Efficiently distributing and managing critical documents.

- Data Collection:

Real-time data tracking for better decision-making and efficiency.

- Labor Management:

Tracking worker schedules and authorizations for efficient staffing.

- Quality Management:

Monitoring quality deviations and ensuring documentation.

- Process Management:

Overseeing the entire production process for traceability and efficiency.

- Maintenance Management:

Proactive equipment issue identification and reduced downtime.

- Product Tracking:

Monitoring product progress and genealogy for informed decisions.

- Performance Analysis:

Comparing results against goals for process improvement.

Evolution of MES Standards

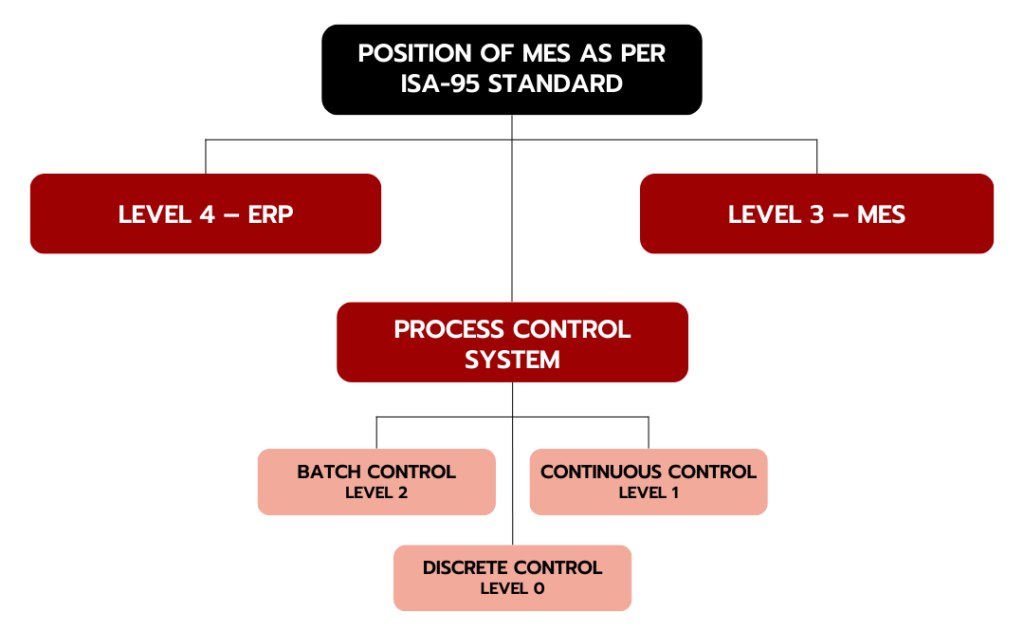

To address the need for standardized terminology and integration between enterprise and control systems, the International Society of Automation (ISA) introduced the ISA-95 standard in the late 1990s. ISA-95 simplifies communication among stakeholders, reduces integration errors, and establishes a clear hierarchy:

Level 4 – ERP: Handles business planning and logistics.

Level 3 – MES: Manages manufacturing operations, bridging business and process control systems.

Level 2 – Process Control (Batch Control): Controls batch processes.

Level 1 – Process Control (Continuous Control): Oversees continuous processes.

Level 0 – Process Control (Discrete Control): Manages distinct manufacturing steps.

MES and ERP Integration

In today’s manufacturing, it’s not MES versus ERP; it’s their collaboration that delivers operational clarity.

- ERP manages schedules, material use, and business information.

- MES monitors real-time manufacturing operations.

Together, they create a holistic view of finance, procurement, supply chain, and manufacturing logistics, enhancing agility and data-driven decision-making. ERP determines what to manufacture, while MES optimizes production, reducing waste and increasing profits.

Seamless ERP Integration:

SAP Manufacturing Execution (SAP ME) takes MES to the next level. It offers seamless integration with all relevant modules in your SAP Enterprise Resource Planning (SAP ERP) system.

What is SAP Manufacturing Execution (SAP ME)?

SAP Manufacturing Execution (SAP ME) is a comprehensive Manufacturing Execution System (MES) solution designed specifically for discrete manufacturing processes. It offers a high level of configurability and customization, making it adaptable to a wide range of industries and diverse production requirements. In essence, it serves as a flexible platform for managing and controlling your production environment with precision and efficiency.

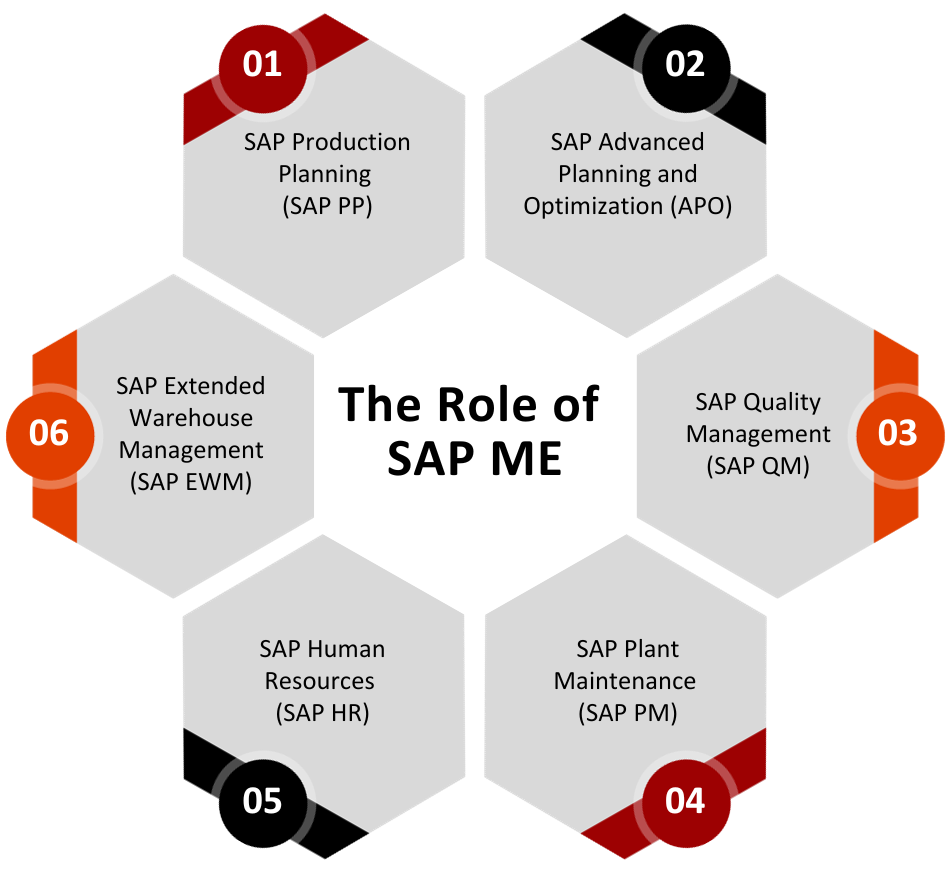

The Role of SAP ME:

SAP ME seamlessly connects with various ERP modules, including:

- SAP Production Planning (SAP PP):

Aligns seamlessly with SAP PP, ensuring that your production planning is not just efficient but also synchronized with real-time data from the shop floor.

- SAP Advanced Planning and Optimization (APO):

With SAP ME, you can take your planning and optimization to the next level, enhancing your ability to meet customer demands and market changes swiftly.

- SAP Quality Management (SAP QM):

Quality is non-negotiable in manufacturing. SAP ME integrates with SAP QM to maintain the highest standards of product quality and compliance.

- SAP Plant Maintenance (SAP PM):

Efficient equipment and facility maintenance is crucial. It keeps your plant maintenance operations well-coordinated with your manufacturing processes.

- SAP Human Resources (SAP HR):

Human resources are the heart of any operation. SAP ME ensures that your HR functions are synchronized with your manufacturing needs, from scheduling to skill management.

- SAP Extended Warehouse Management (SAP EWM):

In today’s supply chain, warehouse management is integral to success. SAP ME integrates seamlessly with SAP EWM to optimize your warehouse operations and inventory management.

Benefits of SAP ME:

- Real-time Visibility:

Provides real-time visibility into your manufacturing operations, allowing you to make informed decisions swiftly and accurately.

- Efficiency Enhancement:

By streamlining your manufacturing processes and integrating them with your ERP system, SAP ME boosts efficiency, reduces downtime, and optimizes resource allocation.

- Quality Assurance:

With SAP ME’s integration with SAP QM, you can ensure that your products consistently meet the highest quality standards, reducing defects and waste.

- Cost Savings:

Efficient operations and better resource utilization lead to cost savings, making it a cost-effective solution for manufacturers.

- Compliance:

For industries with strict regulatory requirements, it ensures compliance by seamlessly integrating with quality management and documentation.

- Future-Ready:

Designed to evolve with your business, allowing you to adapt to changing market demands and technologies.

Conclusion:

In a nutshell, the role of MES and SAP ME cannot be overstated. They are the linchpin that ensures quality, efficiency, compliance, and profitability. Embracing MES and SAP ME is not just a choice; it’s a strategic imperative for success in the modern manufacturing world. They empower manufacturers to excel in a competitive marketplace and unlock the potential for growth, agility, and success.

To explore further or for guidance, contact KaarTech, your partner in manufacturing optimization!

FAQ’s

What is a Manufacturing Execution System (MES)?

A Manufacturing Execution System (MES) is the central software system in manufacturing operations. It monitors, tracks, and controls the entire production process, linking Enterprise Resource Planning (ERP) and process control systems to provide real-time data for improving plant efficiency and production.

What are the core functions of MES?

The core functions of MES include real-time resource tracking, scheduling, data management, quality monitoring, process oversight, maintenance, product tracking, and performance analysis.

What is SAP Manufacturing Execution(SAP ME)?

It is a versatile MES solution designed for discrete manufacturing, offering extensive customization to efficiently manage production processes with precision and adaptability. It seamlessly integrates with various ERP modules for enhanced productivity.

What are the benefits of SAP ME?

The benefits include real-time visibility, enhanced efficiency, improved quality assurance, cost savings, compliance with regulatory requirements, and future readiness for evolving business needs.