Introduction

In today’s fast-paced business, understanding customer preferences is critical for digital transformation. Businesses, on the other hand, typically face significant problems in obtaining complete and real-time customer information. Factors such as limited direct links with end customers, reliance on third-party suppliers, and privacy concerns exacerbate data scarcity. A lack of consumer data hinders organizations’ capacity to get deep insights and successfully drive innovation.

However, SAP Manufacturing Cloud offers a method to overcome these obstacles and generate new opportunities for growth.

SAP offers a number of tools to help manufacturers with their operations, the most popular of which are SAP Manufacturing Execution System (SAP MES) and SAP Manufacturing Integration and Intelligence (MII). SAP ME is a manufacturing execution system (MES) solution focused on real-time production order execution, whereas SAP MII is a manufacturing integration and intelligence platform focused on data integration from various manufacturing sources.

Well, there is a cache for SAP MES, MII, and we do have an excellent solution to this problem, where we will go later.

SAP Manufacturing Execution (ME)

SAP ME is an all-in-one MES system with three main features to consider: centralized operations, automated data gathering, and tracking and resolution. To begin, centralized operations give employees access to assist processes, adapt route materials, and control production. Following that, automated data collection collects all essential production data, such as traceability and quality, monitors adherence to specifications and regulations, integrates the master data process, and so on.

Finally, SAP MES discovers and resolves tracking and resolution issues by producing device history records, tracking and tracing visibility, and data analysis to increase efficiency and dependability.

SAP Manufacturing Integration And Intelligence (MII)

SAP MII is divided into two parts: integration and intelligence. The integration component connects SAP ERP (Enterprise Resource Planning) with plant floor applications, while the intelligence component gives a unified picture of manufacturing activities in real time. SAP MII uses machine-to-machine communication to optimize supply chain management and can be linked with a wide range of systems, providing improved visibility into production.

“The global Manufacturing Execution system market size is expected to grow from USD 13.0 billion in 2022 to USD 20.0 billion by 2027”

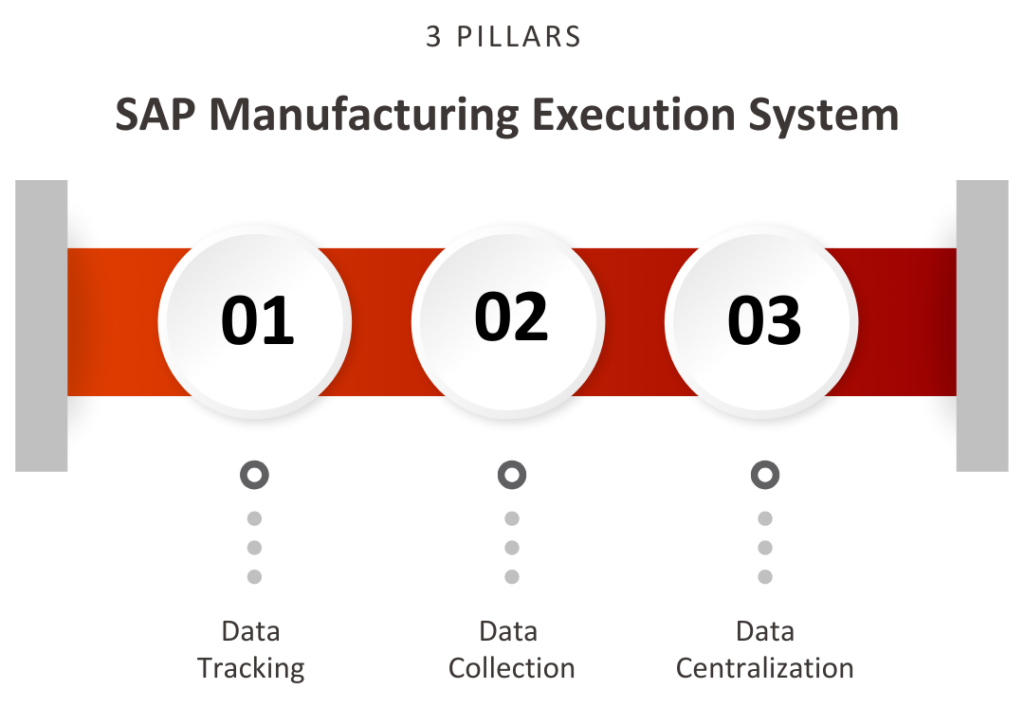

SAP MES’s Three Pillars

SAP MES is based on three key pillars: data tracking, data collection, and data centralization. Let’s take a closer look at each of these features to see how they help manufacturers:

-

Data Tracking

Tracking is all about having real-time visibility into your manufacturing processes. SAP MES allows you to track the status of every machine, work order, and operator on the shop floor. This transparency goes all the way from raw material tracking to completed product distribution. Here’s how tracking with SAP MES can assist your business:

Real-Time Monitoring: SAP MES gives fast access to real-time data, allowing you to identify and respond to production issues as they arise.

Error Reduction: By tracking every stage of the manufacturing process, you can identify and correct faults early on, reducing production failures and waste.

Resource Optimization: Accurate tracking allows for improved resource allocation, ensuring that machinery and labor are utilized as efficiently as possible.

-

Data Collection

Data collection is essential for making informed choices and achieving continual development. SAP MES makes data collecting easier by automating the process and combining useful information from several sources:

Automation: Through machine integration, IoT devices, and barcode scanning, SAP MES automates data gathering, minimizing human error and boosting data accuracy.

Data Transparency: Manufacturers can gather data at numerous touch points throughout the operation, such as production equipment, quality checks, and inventories, promoting data transparency across the operation.

Quality Control: By collecting data on product quality and process parameters, you can assure consistent product quality and industry compliance.

-

Data Centralization

SAP MES definitely shines when it comes to data centralization. It combines data from several sources and consolidates it into a single platform, providing an array of insights and potential for improvement:

Data Integration: SAP MES connects effortlessly with your existing systems, such as ERP, PLM (Product Lifecycle Management), and CRM (Customer Relationship Management), creating a single data environment.

Data Analytics: The centralized data repository allows for advanced analytics and reporting, assisting you in identifying patterns, trends, and areas for improvement.

Decision Support: With a centralized data repository, decision-makers can get accurate, up-to-date information to make informed business decisions.

The Solution:

However, SAP announced that mainstream maintenance and support for SAP ME and SAP MII will end in December 2027,as SAP will encourage users to migrate to the Digital Manufacturing Cloud (DMC)

SAP Digital Manufacturing Cloud

SAP Digital Manufacturing Cloud (DMC) is a manufacturing execution system that resides in the cloud. It offers a scalable, versatile solution for both the discrete and process sectors. SAP DMC performs activities comparable to SAP ME and SAP MII, but can undertake advanced analysis and reporting operations, including Artificial Intelligence (AI) and Machine Learning (ML), as well as fully use the cloud’s capabilities and benefits. This is because SAP DMC uses the Software-as-a-Service (SaaS) business model, which allows AI and ML algorithms to be employed more often.

This is one of the reasons SAP DMC marks a significant step towards Industry 4.0.

DMC offers an innovative architecture that enables high-availability Edge computing and “cloud-based collaboration” for information flow outside the company’s own borders (customers, OEMs, suppliers, and service providers). SAP DMC’s templates and drag-and-drop logic builder enable dealing with manufacturing advanced logic with less customization than MII.

Looking for SAP DMC Migration

If you are presently using SAP ME or SAP MII, it is time to begin planning and executing your migration to SAP DMC – and remember, starting early is essential for allowing yourself ample lead time, since the needs of this migration are easy to underestimate.

The migration from SAP ME/MII to SAP DMC is divided into five stages:

- Pre-Migration Evaluation

This comprises a study of your present and future solution needs, as well as an inventory and assessment of current MII, application code, and artifacts. You’ll also need to develop and finalize clear migration goals and expectations. The migration tasks and expected effort can then be scheduled.

- The Preparation Phase

Resources are budgeted and assigned here, as well as a target environment and proof of concept workshops.

- The Development Phase

The real logic, configuration, and integration to DMC and the ERP solution are built at this phase.

- The Testing and Validation Phase

At this stage, you will test the system and check all users’ roles and authorizations.

- The Deployment Phase

Finally, it is time to deploy the solution, including go-live support, patches, and monitoring to ensure that the new software is seamlessly integrated into your business operations.

Last Thought:

Finally, SAP MES is an effective tool for firms looking to succeed in a data-driven future. It enables organizations to make informed decisions, increase efficiency, and improve quality by tracking, collecting, and centralizing data.

For any queries or expert guidance, feel free to reach out to us at KaarTech. Your path to manufacturing excellence starts here.

FAQ’s

What is a Manufacturing Execution System (MES)?

A manufacturing execution system (MES) is software that monitors, tracks, documents, and controls the full production lifecycle to improve the manufacturing process. An MES enhances quality control, boosts uptime, and lowers inventory and expenses. Improved product tracking and traceability is a primary benefit of a factory execution system, which is crucial for producers who must fulfill regulatory compliance and transparency standards.

What are the three pillars of MES?

The three pillars of Manufacturing Execution System is Tracking, Collecting, Centralization

What are the features of SAP MES?

The core functions of MES include real-time resource tracking, scheduling, data management, quality monitoring, process oversight, maintenance, product tracking, and performance analysis.

Why Should Companies Consider SAP DMC Migration Now?

Discover the key stages of migrating from SAP ME/MII to SAP DMC, emphasizing the importance of early planning and execution to unlock the full potential of digital manufacturing.

One Comment

Comments are closed.

I loved even more than you will get done right here. The picture is nice, and your writing is stylish, but you seem to be rushing through it, and I think you should give it again soon. I’ll probably do that again and again if you protect this walk.