Introduction

The manufacturing industry has come a long way since its inception, and today we find ourselves on the cusp of a new revolution, “Industry 4.0”. With advancements in technology and the rise of automation, the Fourth Industrial Revolution, also known as Industry 4.0, is set to transform the manufacturing landscape as we know it. At the forefront of this revolution is SAP, a leading provider of enterprise software solutions.

In this blog post, we will explore how SAP is revolutionizing the future of manufacturing and beyond with its innovative solutions that’ll enable businesses to optimize operations, enhance productivity, and unlock new levels of efficiency.

From smart factories and predictive analytics to Internet of Things (IoT) connectivity and artificial intelligence, join us as we delve into the exciting world of SAP Industry 4.0 and its potential to reshape the future of manufacturing industry.

The Importance of Industry 4.0 in Manufacturing

The traditional metrics of efficiency and cost optimization are no longer sufficient to measure the success of supply chains in today’s complex business landscape. Manufacturing companies face numerous challenges, including the need to increase productivity while meeting individualized customer demands, responding to supply chain disruptions, and complying with ever-changing regulations. Industry 4.0 offers a strategic approach to address these challenges and turn them into opportunities for tangible business outcomes.

According to a recent study by the MPI Group, implementing Industry 4.0 initiatives has led to a significant increase in profitability for about 63% of manufacturing companies, with 61% already considering it as a competitive differentiator.

Industry 4.0 enables companies to deliver customer demands more effectively, increase productivity, improve agility and visibility, reduce time-to-market, and develop sustainable operations across the shop floor, supply chain and logistics operations.

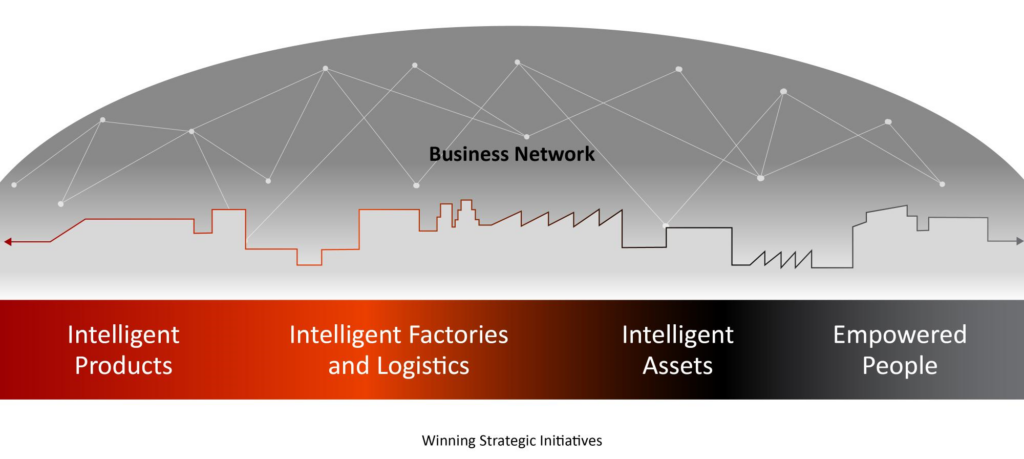

The 4 Winning Strategies by SAP to adopt Industry 4.0

To successfully embrace Industry 4.0 and realize its benefits, companies need to focus on four winning strategic initiatives:

- Intelligent Products

In the era of Industry 4.0, customer demands are more complex and require highly customized, sustainable, and high-quality products. Intelligent products are designed to meet these unique configuration needs and are equipped with sensors to capture real-time data on their performance.

This allows manufacturers to monitor how products are used, optimize their performance, and offer new business models such as asset ownership and maintenance agreements. Intelligent products also extend to process industries, where digital services provide guidance on product application and optimization.

- Intelligent Factories and Logistics

Intelligent factories leverage real-time data and artificial intelligence to run autonomously and adaptively. These factories are adaptable, agile, and capable of managing variable production configurations and demand volumes.

By embracing technologies such as IoT, machine learning, and automation, these factories can

➔ Reduce operational costs

➔ Increase delivery capabilities

➔ Improve asset performance

➔ Enhance productivity

➔ Process efficiency and mitigate risks

Intelligent logistics, closely integrated with manufacturing, optimizes warehouse and production supply lines, enabling efficient operations and full digital transparency. Smart sensing with IoT devices automates goods receipt and issue, triggers Kanban processes, and ensures seamless production supply management.

- Intelligent Assets

To optimize operational asset performance, companies should adopt intelligent asset management practices. Utilizing data from IoT sensors, predictive analytics, simulation, and machine learning enables the implementation of effective predictive maintenance strategies, minimizing downtime. Furthermore, integrating maintenance operations across the enterprise and fostering collaboration with equipment suppliers and service providers contribute to improved profitability, productivity, and positive environmental and social outcomes.

- Empowered People

While automation plays a crucial role in Industry 4.0, the role of operators and maintenance technicians remains essential. Empowered people are equipped with tools and real-time information to make better decisions, monitor operations, and handle exceptions.

By providing contextual data and combining it with corporate business data, operators can reduce response times, improve efficiency, and detect root causes faster. Technology plays a vital role in empowering people, providing them with intuitive interfaces, natural language processing, and access to real-time data.

SAP’s Approach to Industry 4.0

SAP offers a comprehensive approach to Industry 4.0, focusing on connecting the entire company, moving to data-driven business processes, and standardizing and scaling operations.

- Connect the Entire Company

SAP’s Industry 4.0 strategy goes beyond factory-focused initiatives, aiming to connect the entire organization. By orchestrating sales, engineering, maintenance, service, finance, and logistics with manufacturing, SAP enables companies to transform their business processes and achieve a competitive edge. SAP’s ability to connect core business operations and processes across the enterprise helps companies streamline their operations, optimize resource allocation, and improve information flow.

- Move to Data-Driven Business

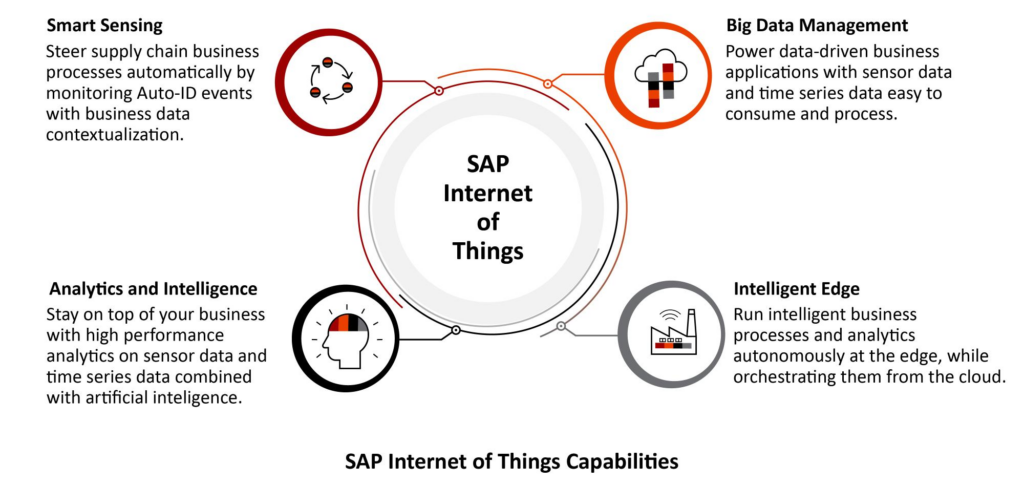

SAP’s strength lies in its ability to turn raw data into actionable insights and improved business process automation. By deeply embedding machines, sensors, and IoT data into business processes, SAP enables companies to leverage artificial intelligence and analytics to enhance productivity and agility in industrial environments. SAP’s comprehensive capabilities for smart sensing, big data management, intelligent edge, and analytics empower companies to make data-driven decisions, automate processes, and increase visibility and efficiency.

- Standardize and Scale Operations

Standardization is a key aspect of Industry 4.0, allowing companies to run standardized operational processes across global resources. By eliminating non-value-add operations and embracing lean principles, companies can shift production flexibly across facilities and optimize capacity utilization. SAP’s robust cloud solutions enable companies to scale Industry 4.0 across global operations, implement standardized processes, and drive innovation.

Additionally, SAP’s engagement in standardization bodies and industry consortiums ensures that its solutions align with industry standards and best practices.

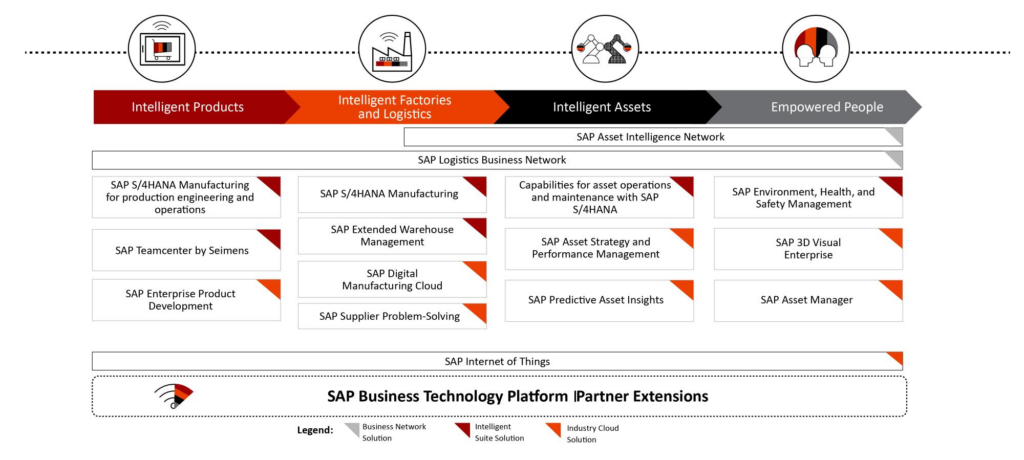

SAP Industry 4.0 Solutions

SAP offers a broad solution portfolio for Industry 4.0, combining its expertise in design, manufacture, logistics, and operations into a comprehensive offering. These solutions empower companies to steer their business resources in real-time, make informed decisions, and optimize their operations.

Current Solutions:

Industry 4.0 strategy integrates a wide range of SAP solutions, creating a holistic offering that champions strategic initiatives and industry best practices. Among these are leading solutions like

➔ SAP Enterprise Product Development

➔ SAP Digital Manufacturing Cloud

➔ SAP Asset Strategy and Performance Management

➔ SAP Environmental Health and Safety applications

At the core lies SAP S/4HANA, integrated with the SAP Business Technology Platform and cloud-based applications, extending the core functionalities to encompass innovative Industry 4.0 scenarios and seamless connectivity with factory devices

In addition, SAP Internet of Things (IoT) acts as the backbone for data management, offering comprehensive capabilities for intelligent sensing, big data handling, analytics, and intelligent edge technology. This empowers device connectivity, data lake management, edge processing, robust rules engine implementation, and business contextualization of IoT data.

With SAP IoT, orchestration of business processes occurs in a central cloud environment, supported by edge processing to overcome challenges such as latency and intermittent connectivity at manufacturing or plant sites. Users enjoy flexibility and choice in data lake storage and management between SAP and various hyperscalers.

Future Solutions:

Looking ahead, SAP’s solution portfolio is evolving into an integrated digital operations management suite of modular solutions. The strategy revolves around providing comprehensive capabilities necessary for running end-to-end factory and plant operations at an enterprise scale, driven by data-centric processes. These capabilities encompass discrete and process manufacturing operations, incorporating modular production, hyper automation, and application validation tailored to industries like life sciences.

The suite covers the entire manufacturing operations value chain, spanning requirements management, manufacturing engineering, production planning and dispatching, logistics, shop floor execution, insights and intelligence, quality management, and asset operations. The imperative is to enable data-driven end-to-end business processes leveraging the industrial Internet of Things, coupled with big data management, edge computing, and machine learning capabilities to fuel process automation and intelligence.

This modular deployment aligns seamlessly with ERP processes like SAP S/4HANA and encompasses various capabilities:

– Production engineering streamlines the conversion of engineering to manufacturing bill-of-materials and facilitates seamless handling of changes, even in complex order processes.

– Production planning and scheduling optimize resources and equipment, integrating cross-plant network planning and offering solutions for disruptions on the shop floor.

– Mission control oversees production execution and process control, ensuring seamless material delivery and supporting modular manufacturing setups.

– Mission assurance provides insights into global plant and production performance, offering advanced quality management and asset performance maximization.

– Smart sensing enhances logistics and plant maintenance processes, fostering higher levels of automation and efficiency.

At the heart of these operations lies the Industrial Internet of Things Foundation, providing a unified data model, big data management, decision engine framework, and edge computing capabilities. This facilitates seamless connectivity among machines, sensors, and devices, adhering to standards such as the asset administration shell and OPC-UA.

Implementing Industry 4.0 with SAP

Implementing Industry 4.0 requires a holistic approach, and SAP offers a range of services and solutions to simplify and accelerate the journey. These services include pre-built packages, customizable implementation services, and value assurance services for partner-led implementations. SAP’s innovation hubs also provide workspaces for companies to explore Industry 4.0 possibilities and develop high-value use cases.

With SAP’s support, manufacturing companies can embark on their Industry 4.0 journey, unlock the potential of digital transformation, and reap the benefits of increased productivity, improved profitability, and enhanced competitiveness.

For inquiries or expert guidance on your digital transformation journey, reach out to KaarTech. Let us be your navigator through the landscape of Industry 4.0.

FAQ’s

What is Industry 4.0, and why is it important in manufacturing?

Industry 4.0, also known as the Fourth Industrial Revolution, signifies the integration of advanced technologies like IoT, AI, and automation into manufacturing. It is crucial for addressing challenges, increasing productivity, and turning disruptions into opportunities. According to a study, implementing Industry 4.0 initiatives has led to a significant increase in profitability for about 63% of manufacturing companies.

What are SAP’s winning strategies for adopting Industry 4.0?

SAP emphasizes four strategic initiatives: Intelligent Products (customized and sensor-equipped), Intelligent Factories and Logistics (real-time data and AI-driven autonomy), Intelligent Assets (predictive maintenance and IoT sensor data utilization), and Empowered People (equipping operators with real-time information and tools).

How does SAP approach Industry 4.0, and what are its core focuses?

SAP’s Industry 4.0 approach involves connecting the entire company, moving to data-driven business processes, and standardizing and scaling operations. The focus is on orchestrating various business functions, turning data into actionable insights, and implementing standardized processes across global resources.

What Industry 4.0 solutions does SAP offer, and how are they evolving?

SAP provides a comprehensive portfolio of Industry 4.0 solutions, including SAP S/4HANA, SAP Digital Manufacturing Cloud, and SAP Asset Strategy and Performance Management. The evolution of SAP’s solutions is towards an integrated digital operations management suite, offering modular solutions for end-to-end factory and plant operations, driven by data-centric processes and incorporating IoT, big data, edge computing, and machine learning capabilities.

One Comment

Comments are closed.

Magnificent beat I would like to apprentice while you amend your site how can i subscribe for a blog web site The account helped me a acceptable deal I had been a little bit acquainted of this your broadcast offered bright clear idea