Introduction

Digital manufacturing, the new fundamental principle of Industry 4.0, integrates multiple technologies and techniques in production chains to optimize product life cycles. This benefits businesses by allowing leaner and more dynamic work processes, as well as the opportunity to give new value-added services to customers. In this blog, you’ll learn about digital manufacturing, its benefits, and its influence on many sectors.

What is Digital Manufacturing?

Digital manufacturing, also known as Industry 4.0, is a comprehensive approach to production that uses digital technologies to optimize the entire product lifecycle, from design and prototyping to production and maintenance. It integrates manufacturing operations to streamline and improve design, production, servicing, and other processes.

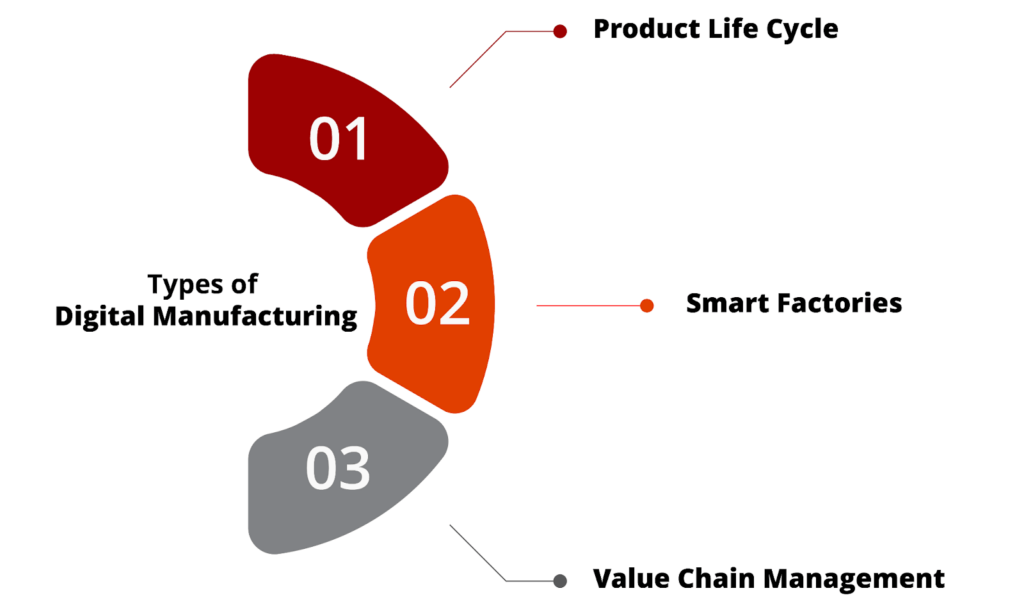

Types of Digital Manufacturing:

Digital manufacturing can be used in three areas: product lifecycle management, smart factories, and value chain management.

- Product Life Cycle

Digital manufacturing can make it simpler to change design parameters, forecast raw material demand, and provide superior customer service throughout the product life cycle, which begins with engineering design and progresses through sourcing, production, and maintenance.

- Smart Factories

Machines, sensors, and tools in smart factories collect real-time data that can be transformed into insights that improve the efficiency of your processes. Insights can then be utilized to improve productivity and reduce costs by changing procedures and controls.

- Value Chain Management

The field of value chain management is focused on reducing the amount of resources necessary to run a manufacturing process while maintaining quality.

Importance of digital manufacturing:

The importance of digital manufacturing are indeed Connectivity, Intelligence, Digital twin and Automation. These key elements are fundamental to the transformation of traditional manufacturing processes into modern, efficient, and data-driven operations.

- Connectivity:

Connectivity refers to the integration of numerous devices, equipment, systems, and processes over a network, most often the Internet of Things (IoT). It allows for easy connection and data sharing between various components inside the industrial environment.

- Intelligence:

Intelligence in digital manufacturing entails analyzing massive amounts of data created during production using modern technologies such as artificial intelligence (AI), machine learning (ML), and data analytics.

- Digital twin:

A virtual clone of a real manufacturing system is referred to as a digital twin. It enables producers to virtualize and test processes, goods, and equipment before applying changes in the actual world. This decreases the risks and expenses of experimenting.

- Automation:

Robotics, autonomous systems, and computer-controlled processes are used in digital manufacturing to undertake activities that were formerly performed by people. It encompasses everything from basic, repetitive procedures to complicated decision-making processes.

Why is process management important for digital manufacturing?

Business Process Management (BPM) improves end-to-end production flows. Its primary purpose is to provide value to products and services while also assisting in the achievement of strategic goals.

Modeling, documenting, providing value, monitoring, and systematization are all part of process management, which ensures that operations are carried out in a cyclical manner.

- Modeling:

Modeling is the process of visualizing a process using flowcharts, diagrams, or process maps. These models assist stakeholders in comprehending how a process operates, including its steps, inputs, outputs, and dependencies.

- Documentation:

Documentation involves recording all relevant information about a process, including its objectives, procedures, roles and responsibilities, and any associated documentation

- Providing Value:

The primary goal of any process is to provide value to the organization and its clients. Value can be in the form of products, services, or improved outcomes.

- Monitoring:

Monitoring is the continual tracking and evaluation of a process’s performance using key performance indicators (KPIs) and other relevant data.

- Systematization:

The process of standardization and institutionalizing better procedures and best practices throughout an organization is known as systematization.

Challenges of Digital Manufacturing:

Digital Manufacturing holds great promise, but it also faces several challenges that need to be addressed for its successful adoption and implementation across industries. These challenges include:

- High Initial expenditure:

The upfront investment required to implement technologies can be substantial. This includes purchasing advanced equipment, software, and infrastructure, as well as training the workforce. Smaller companies, in particular, can struggle to allocate the necessary resources.

- Data Management:

The massive amount of data created by digital manufacturing processes must be gathered, stored, and analyzed properly. To extract important insights and make educated decisions, businesses require comprehensive data management and analytics techniques.

- Supply Chain Disruption:

Because digital manufacturing frequently includes localized, on-demand production, it has the potential to disrupt traditional supply networks. To accommodate these changes and minimize interruptions, businesses must alter their supply chain strategy.

- Quality Control:

It is critical to ensure product quality in a digital production environment. To avoid faults and maintain high product standards, real-time monitoring, data analytics, and quality control procedures must be in place.

Benefits of digital manufacturing:

- Process optimization:

Allows for more fluid and standardized operations, resulting in fewer mistakes and rework.

- Cost reduction:

Makes the best use of existing resources, resulting in lower costs and higher revenues.

- Sustainability:

By reducing waste, optimizing energy use, and improving resource management, can lead to more sustainable practices.

- Factory modernization:

Manual procedures are becoming less prevalent as they are replaced by quicker jobs done by more technology and accurate instruments.

- Data-driven decision-making:

Managers can access real-time market and production data, providing them with a strong set of data for better decision making and greater business competitiveness.

- Improve Quality:

Quality is improved because real-time monitoring and analytics guarantee that goods satisfy high quality requirements, decreasing faults and recalls.

Impact of Digital manufacturing on various industries:

Digital Manufacturing’s transformative potential isn’t limited to a single industry. It is reshaping manufacturing across various sectors:

- Automobile:

Enables quick prototyping of innovative vehicle designs and the use of modern materials, resulting in safer and more fuel-efficient cars.

- Aerospace:

Digital technologies are being used by aircraft makers to create lightweight, efficient designs and expedite production processes.

- Healthcare:

Customized medical equipment and prostheses can be made rapidly and affordably, increasing patient care.

- Consumer Electronics:

Enables the manufacturing of smaller, more powerful, and energy-efficient products.

- Wholesale:

Through real-time data analytics, digital manufacturing helps wholesalers to optimize inventory management. It can anticipate demand and guarantee that the proper goods are supplied in the right quantities, eliminating overstock and understock.

Last thought:

Digital Manufacturing is more than just a technology trend; it is a fundamental revolution that is transforming the manufacturing environment across sectors.

Businesses that can embrace this shift and adapt to the benefits it brings will be well-positioned to flourish in future manufacturing. It is not a passing fad; it is a revolution that will shape the future of how we design, manufacture, and deliver things to the world.

As you venture into this transformative journey, KaarTech stands as your trusted partner for digital transformation. Click here to learn more and embark on your digital evolution with us.

FAQ’s

What is the primary goal of digital manufacturing?

Digital manufacturing aims to optimize production processes using digital technologies throughout the entire product lifecycle, from design to maintenance. It enhances efficiency, reduces errors, and enables better decision-making.

Why is connectivity crucial in digital manufacturing?

Connectivity integrates devices and systems through the Internet of Things (IoT), enabling seamless data sharing and communication. This interconnectedness allows for real-time monitoring and collaboration, enhancing operational efficiency.

What challenges does digital manufacturing face?

Challenges include initial investment costs, effective data management for insights, potential supply chain disruptions due to localized production, and ensuring high-quality standards in a digital environment.

What industries are impacted by digital manufacturing?

Various sectors, such as automotive, aerospace, healthcare, consumer electronics, and wholesale, are experiencing transformation. It enables rapid prototyping, efficient designs, personalized medical equipment, and optimized inventory management.