Introduction

Optimal usage of resources along with increasing profits is a prime requisite of any business owner, right? When human power is insufficient to handle some of the most difficult problems, technology has assisted us in finding solutions. For every major problem that is resolved via the use of technology, numerous smaller issues are also resolved as a ripple-down effect.

Businesses need to make wise strategic decisions and use existing resources effectively to survive in the current competitive environment. Many businesses are implementing intelligent process automation solutions to reduce resource waste.

You should absolutely think about using a process automation solution if you currently run a business or are thinking about starting one. To begin with let’s start with every object we use, from where do we get them, well, of course, some manufacturing unit right?

So, how does all these kinds of automation work for the manufacturing sector? Are the industries with huge production units utilizing their resources in a rightful way? Are their plants well-operated? How much are those industries spending on maintenance activities?

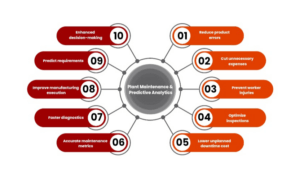

For all those manufacturers and businesses that own huge production plants out there, this is a shout-out to a solution that’s available on the SAP Store, Plant Maintenance, and Predictive Analytics, which focuses on turning the tables with the power of automation for the manufacturing industry across the globe.

With that being said, Let’s start with understanding the benefits that the solution brings for the Manufacturing Industries.

Key Benefits for the Manufacturing Industry

- Reduce errors in your product

- Drastically scale out unnecessary expenditure

- Reduce errors in your product

- Drastically scale-out unnecessary expenditure

- Avoid worker’s injury

- Optimize Inspection Techniques

- Reduce the cost of unplanned downtime

- Obtain correct metrics or KPIs regarding maintenance

- Minimize time spent on diagnostics

- Enhance manufacturing execution systems

- Forecast the requirements

- Make better decisions with best-in-class analytics

We believe that the prospects of the solution are clearly defined above, time to know what is the solution and how it works;

Evolution of Plant Maintenance and Predictive Analytics Solution

The greatest of ideas are brought out only when you plan to test it out, right?

And that’s exactly how the ideation of the Plant Maintenance and Predictive Analytics began, our experts were working on various ideations under the guidance of Mr.Srinivasan Subbiah and Mr.Girish M P. The solution didn’t just stand unique in the SAP Analytics Cloud Hackathon 2020 but also badged the award.

That’s exactly when the chiefs of KaarTech stepped in and decided to fund the process, the process of inventing one tool that plans and predicts the working of all the production plants you own. So let’s dive in and learn how the tool operated;

How Plant Maintenance and Predictive Analytics Solution Works?

The application gathers its raw data from the plant maintenance activities and stores it in S/4HANA’s unique Core Data Service (CDS) views which is later used by the SAP Analytics Cloud (SAC) Model.

The Analytical and Planning Model will record data from Actual, Planning, and Simulation, and for Prediction, a Predictive Scenario will be utilized to train data and develop the model.

Planning Scenario

Here we utilize the SAC Story and SAC Analytical Application to visualize the data from S/4HANA custom CDS views that have been developed into graphs, charts, or tables.

By understanding the Planning Scenario through the CDS views a Planning Model will be created.

The CDS views are also used for creating analytical and Actual Simulation Scenarios.

Predictive Scenario

The CDS views play a key role in developing the data set in SAC for the creation of a predictive scenario.

The predictive scenario will then be developed using this data set. The output data set, which will be used in a model offers valuable predictions once it has been trained.

Then, a story summarizing the data in an understandable format will be created using the models from all of the aforementioned scenarios.

Additionally, models will be used by analytical applications, which will enable users to quickly generate dashboards using pre-established KPIs.

Features Embedded in the Plant Maintenance Predictive Analytics Solution

➔ The tool offers you major functions like Reporting, Planning, Prediction, Simulation, and Analytics by efficiently utilizing the past data for every plant you own.

➔ The reports provide us insights on the plant KPIs like plant expenditure, equipment that undergoes maximum breakdowns, mean duration of failures, the efficiency of the plant, etc.

➔ Under prediction, the tool effectively predicts information about the plant’s breakdown probability, service dates, and its lifetime of working.

➔ After providing us with the analysis reports and prediction PMPA helps you to draft a perfect production strategy through analytics, planning, and simulation.

➔ Planning gives you insights into the plants under maintenance, plants allocated to other orders production, the plant’s duration of operation, etc.

➔ Then comes the simulator which auto-calculates the Average Downtime schedule by taking the count of production along with the plants involved for the production activity.

➔ Finally, Analytics allows us to choose the KPIs and provide us with the details and charts of the chosen KPIs.

Are you still confused? Check out this video and to know more about the tool, click on this link, and don’t forget that our experts are all set to deliver the best solution to improve and automate your business!

FAQ’s

What is the significance of Plant Maintenance and Predictive Analytics in the Manufacturing Industry?

Plant maintenance and predictive analytics are vital for manufacturing industries as they minimize product errors, reduce unnecessary expenditures, prevent worker injuries, optimize inspection techniques, and minimize unplanned downtime costs.”

What are the benefits of Plant Maintenance?

Plant Maintenance provides several key features and benefits, including reducing unexpected maintenance costs and maintaining plant productivity, minimising downtime at a low cost, increasing machine efficiency and quality.

What is the role of predictive analytics in manufacturing?

The role of predictive analytics in the maintenance of any machinery of the manufacturing unit is to promptly alert management of any potential breakdowns or services necessary for the machinery.

What are the tools offered by Plant Maintenance and Predictive Analytics?

The tool offers you major functions like Reporting, Planning, Prediction, Simulation, and Analytics by efficiently utilizing the past data for every plant you own.