Hey there,

- Are you finding it difficult to manage your company’s supply chain to meet the demands of a market that is rapidly changing?

- Do you find it difficult to simplify procedures, cut expenses, and improve overall productivity?

If the answers for the above-mentioned questions are “yes”. Then this blog is for you.

Continue reading to learn more about Supply chain management.

Effective supply chain management is essential for your business to meet customer requirements and remain competitive in today’s changing business environment. One key tool that helps your business integrate operations and get greater visibility throughout the supply chain is SAP Supply Chain Management (SAP SCM).

In this blog, we’ll get an in-depth understanding of SAP SCM, the process involved, and its factors. But before knowing the factors that facilitate successful supply chain management, let’s skim through the solution that can make your supply chain more efficient.

Understanding SAP Supply Chain Management

SAP Supply Chain Management is an integrated software suite that optimizes end-to-end supply chain processes. It makes the supply network more visible, makes demand-driven planning easier, and promotes effective teamwork.

Let’s look at the process involved in implementing it.

Process in SAP SCM Implementation

- Project Planning: Establish the project’s goals, schedule, scope, and resource requirements through project planning.

- Business Blueprinting: Work together with stakeholders to draft a comprehensive plan that outlines system requirements and business processes.

- System Configuration: Set up its modules like demand planning, supply network collaboration, and production planning that can correlate with the business blueprint.

- Customization and Development: Create unique features and improvements to satisfy business requirements.

- Data Migration Execution: Proceed with the data migration strategy to make sure that pertinent data is seamlessly transferred into this system.

- Integration Testing: Carry out thorough testing to confirm that SAP SCM is integrated with other SAP modules and external systems.

- User Instruction: Educate end users on the features, workflows, and system navigation of this solution

- Deployment and Go-Live: Introduce the system into the operational setting while checking system performance and addressing any possible problems.

- Post-Implementation Support: Offer continuing assistance, responding to user inquiries, fixing problems, and consistently enhancing system efficiency.

- Monitoring and Optimization: Make use of monitoring tools to keep tabs on system performance, examine information, and pinpoint areas in need of improvement.

Let’s now focus on the core part of this blog.

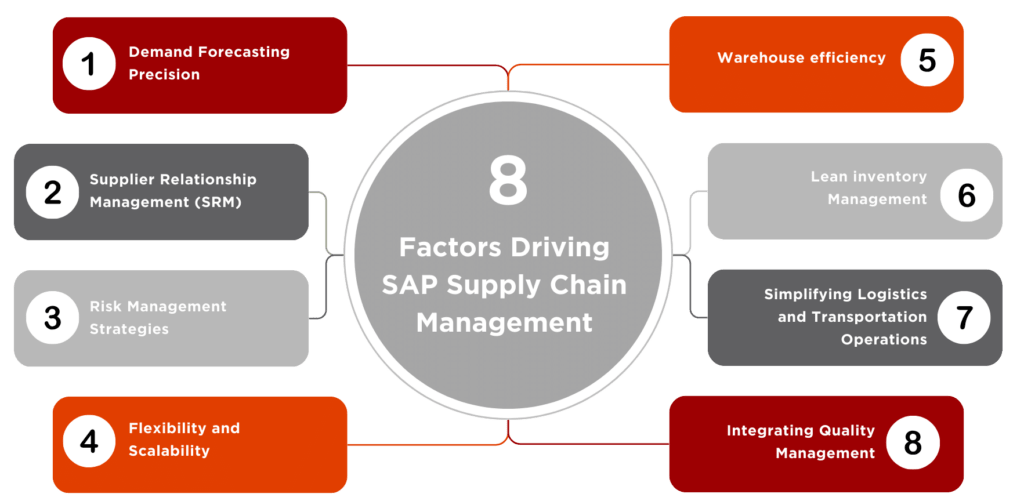

Top 8 factors driving SAP Supply Chain Management

SAP Supply Chain Management provides an extensive range of tools and features to help your company simplify their operations, improve workflows, and achieve success.

But installing SAP SCM successfully isn’t enough; you also need to take a calculated approach and pay attention to important details that have the power to create or break the system’s efficacy.

Here are the top 8 critical factors determining it:

1. Demand Forecasting Precision

It is the degree of accuracy with which a supply chain management system, including SAP SCM, projects future demand for goods and services. Its accurate consumer demand forecasting is based on previous data analysis and sophisticated statistical techniques.

It improves demand forecasting accuracy by utilizing complex algorithms and data analytics. This helps your company optimize inventory levels, reduce stockouts, and optimize their supply chain processes for increased productivity and profitability.

2. Supplier Relationship Management (SRM)

A key component of SAP Supply Chain Management’s success is the strategic strategy known as Supplier Relationship Management (SRM). It is the management of supplier contacts with the goals of improving collaboration, simplifying the procurement process, and producing cost savings.

Your business can reduce risks, improve supply chain efficiency, and stimulate innovation through productive supplier relationships by utilizing SRM within this system. Your business can attain increased efficiency, agility, and competitiveness in the current dynamic market scenario by implementing an integrated approach.

3. Risk Management Strategies

Successful risk management techniques are essential to SCM performance. Your business can now address any interruptions and uncertainties in their supply chains proactively by utilizing strategies like risk identification, evaluation, and mitigation.

In today’s fast-paced corporate world, putting strong risk management techniques into practice not only protects operations but also promotes agility, resilience, and competitive advantage. By utilizing its features, like predictive modelling and real-time data analysis, your business can boost supplier collaboration, optimize inventory levels, and reduce supply chain risks.

4. Flexibility and Scalability

Being flexible guarantees that your company can rapidly modify its strategy in response to changing market conditions. Scalability is the ability of a system to manage growing amounts of information or operations without sacrificing efficiency.

When combined, they give your company the ability to reduce workflows, adapt to shifting customer needs, and grow effectively. To put it technically, scalability refers to strong architecture, distributed computing, and effective resource allocation, and flexibility refers to features like flexible processes and customized modules. Enhancing operational agility and promoting business growth are made possible by these qualities.

5. Warehouse efficiency

It refers to the best use of a warehouse’s resources and procedures to increase output while lowering expenses. Specifically, it refers to optimizing order fulfilment, inventory control, and logistics processes inside the system.

Accurate inventory, efficient picking and packing procedures, space use, and worker productivity are important variables. Utilizing its features like inventory optimization, demand forecasting, and analytics, your company can improve warehouse productivity, which in turn leads to better customer satisfaction, shorter lead times, and higher profitability.

6. Lean inventory Management

The effectiveness of it depends on lean inventory management. It minimizes excess stock, lowers expenses, and boosts productivity while optimizing inventory levels to match demand. It guarantees that resources are used efficiently by utilizing methods like demand forecasting, Kanban systems, and just-in-time inventory.

Through process optimization and supply chain alignment, your company can improve customer satisfaction and responsiveness. Your business striving for operational excellence and sustainable growth within this framework will find this strategy invaluable as it cultivates agility, resilience, and competitiveness in the market landscape.

7. Simplifying Logistics and Transportation Operations

The key to SAP Supply Chain Management’s success is its ability to smoothly facilitate transportation and logistical processes. It uses the latest technology to decrease delays, cut costs, and improve efficiency in the flow of products. These technologies include tracking, route optimization, and predictive analytics.

This efficient method guarantees on-time delivery, increased client satisfaction, and more effective use of company resources. Essentially, it helps your business achieve operational excellence by precisely coordinating and changing their logistical activities.

8. Integrating Quality Management

Processes that guarantee goods and services live up to specifications and client expectations are included in quality management. Your business can boost client satisfaction, operational efficiency, and product reliability by smoothly integrating quality control methods into supply chain management workflows.

Gaining a competitive advantage in the market is made possible by implementing technical terms like Six Sigma, Total Quality Management (TQM), and Lean concepts in SCM. These phrases help simplify processes, minimize waste, and promote continuous development.

The above-mentioned are the most important aspects of SAP SCM. These eight powerful features greatly enhance overall effectiveness and strong functionality.

Conclusion

BCI Supply Chain Resilience Report 2023 say, “The primary repercussion of supply chain disruptions is an 84.6% rise in the cost of operations.”

To put it briefly, SAP Supply Chain Management is the cornerstone of an adaptable and robust business ecosystem. It advances your supply chain with features like demand-driven planning and predictive analytics.

Put your trust in KaarTech as your implementation partner to start this journey of transformation. With a track record of 20 years of SAP expertise and 500+ customers globally, we guarantee flawless workflows, seamless integration, and unmatched support.

Use SAP SCM to improve your supply chain capabilities and let us be your implementation partner for unmatched productivity and long-term success.

Contact us to know more about our services!

FAQ’s

How does SAP SCM enhance supply chain visibility?

It boosts supply chain visibility by integrating data across the entire network, providing real-time insights, tracking inventory, and facilitating collaboration, empowering businesses to make informed decisions and optimize processes efficiently.

What specific features drive efficiency in supply chain management with SAP?

It enhances efficiency through features like demand planning, inventory optimization and logistics management. Seamless integration of these elements streamlines operations and promotes agile, data-driven decision-making for businesses.

What role does SAP SCM play in demand forecasting and planning?

It facilitates accurate demand forecasting and planning by leveraging advanced analytics and real-time data, enabling organizations to anticipate market trends, optimize inventory levels, and enhance overall operational efficiency.

What features contribute to SAP SCM’s supply chain resilience?

Its Supply chain resilience is bolstered by real-time visibility, demand sensing, risk management tools, collaborative supplier networks, adaptive planning, and robust analytics, ensuring agility and responsiveness to dynamic challenges.